10.实现close_loop_velocity_control闭环速度控制

小于 1 分钟

10.实现close_loop_velocity_control闭环速度控制

具体实现

BLDCMotor.cpp#include "Arduino.h"

#include "BLDCMotor.hpp"

BLDCMotor::BLDCMotor(uint8_t polePairs, float power_supply_voltage)

{

this->polePairs = polePairs;

this->power_supply_voltage = power_supply_voltage;

}

void BLDCMotor::connectDriver(BLDCDriver *driver)

{

this->driver = driver;

}

void BLDCMotor::connectSensor(Sensor *sensor)

{

this->sensor = sensor;

}

void BLDCMotor::connectCurrentSensor(CurrentSensor *currentSensor)

{

this->currentSensor = currentSensor;

}

void BLDCMotor::connectCommand(Command *command)

{

this->command = command;

}

void BLDCMotor::initFOC()

{

if (this->currentSensor)

{

this->currentSensor->initSensor();

this->currentSensor->alignSensor();

}

if (this->driver)

{

this->driver->initDriver();

this->driver->enableDriver(true);

this->driver->setPhraseVoltage(0, 0, 0);

}

if (this->sensor)

{

this->sensor->initSensor();

this->sensor->connectMotor(this);

this->sensor->alignSensor();

this->sensor->init();

this->sensor->update();

}

}

void BLDCMotor::loopFOC()

{

if (this->sensor)

this->sensor->update();

switch (controlMode)

{

case ControlMode::Voltage:

this->open_loop_voltage_control(0, target);

break;

case ControlMode::Current:

this->close_loop_current_control(target);

break;

case ControlMode::Velocity:

this->close_loop_velocity_control(target);

break;

case ControlMode::Position:

this->close_loop_velocity_control(target);

break;

default:

break;

}

}

/**

* 设置控制模式

*/

void BLDCMotor::setMode(ControlMode controlMode)

{

switch (controlMode)

{

case ControlMode::Unknow:

break;

case ControlMode::Voltage:

break;

case ControlMode::Current:

// 官方 Simple FOC Shield v2.0.4 开发板 with 2808云台电机

// this->pid_id_controller = PIDControler(2.8, 200, -0.005, this->limit_voltage, 0);

// this->pid_iq_controller = PIDControler(2.8, 200, -0.005, this->limit_voltage, 0);

// 艾尔塞电子 Simple FOC Shield v2.0.4 开发板 with 2808云台电机

// this->pid_id_controller = PIDControler(2, 1000, 0, this->limit_voltage, 0);

// this->pid_iq_controller = PIDControler(2, 1000, 0, this->limit_voltage, 0);

// 官方 Simple FOC Shield v2.0.4 开发板 with 2804-100kv 云台电机

this->pid_id_controller = PIDControler(20, 500, 0, this->limit_voltage, 400);

this->pid_iq_controller = PIDControler(20, 500, 0, this->limit_voltage, 400); // 完美

break;

case ControlMode::Velocity:

// 官方 Simple FOC Shield v2.0.4 开发板 with 2808云台电机

// this->pid_id_controller = PIDControler(2.8, 0.01, 0, this->limit_voltage, 0);

// this->pid_iq_controller = PIDControler(2.8, 0.01, 0, this->limit_voltage, 0);

// this->pid_velocity_controller = PIDControler(0.5, 2.5, 0, this->limit_current, 0); // kp<1; ki<=10;

// 艾尔塞电子 Simple FOC Shield v2.0.4 开发板 with 2808云台电机

// this->pid_id_controller = PIDControler(2, 1000, 0, this->limit_voltage, 0);

// this->pid_iq_controller = PIDControler(2, 1000, 0, this->limit_voltage, 0);

// this->pid_velocity_controller = PIDControler(0, 0, 0, this->limit_current, 0);

// 官方 Simple FOC Shield v2.0.4 开发板 with 2804-100kv 云台电机

this->pid_id_controller = PIDControler(20, 500, 0, this->limit_voltage, 400); // kp可以设置到30 但取其 2/3 为 20,余量留给ki发挥 roc设置为400是为了

this->pid_iq_controller = PIDControler(20, 500, 0, this->limit_voltage, 400);

this->pid_velocity_controller = PIDControler(0.01, 0.05, 0.0001, this->limit_current, 20); // 非常完美 但当电压为12v时最好设置电流限制为1

break;

case ControlMode::Position:

// this->pid_id_controller = PIDControler(2.8, 0.01, 0, this->limit_voltage, 0);

// this->pid_iq_controller = PIDControler(2.8, 0.01, 0, this->limit_voltage, 0);

// this->pid_velocity_controller = PIDControler(0.5, 2.5, 0, this->limit_current, 0);

// this->pid_position_controller = PIDControler(0, 0, 0, this->limit_velocity, 0);

break;

default:

break;

}

this->controlMode = controlMode;

}

void BLDCMotor::setTarget(float target)

{

this->target = target;

}

/**

* @details

* 电角度=机械角度*极对数

* @return [0,2PI] => [0,UINT16_MAX]

*/

uint16_t BLDCMotor::electricalAngle()

{

return this->sensor->getPositon() * polePairs;

}

/**

* 设置相电压

* @param u_d int16_t [-32768,32767] 表示 [-1,1] 精度:1/32768 = 0.0000605

* @param u_q int16_t [-32768,32767] 表示 [-1,1]

* @param e_angle uint16_t [0,65535] 表示 [0,2PI] 精度:360°/65535 = 0.00549°

*/

void BLDCMotor::setPhraseVoltage(int16_t u_d, int16_t u_q, uint16_t e_angle)

{

int16_t sin, cos;

// 计算三角函数

_sincos(e_angle, &sin, &cos);

// 帕克逆变换

int16_t u_alpha = ((cos * (int32_t)u_d) + (sin * -(int32_t)u_q)) / INT16_MAX;

int16_t u_beta = ((sin * (int32_t)u_d) + (cos * (int32_t)u_q)) / INT16_MAX;

// 克拉克逆变换(等幅值形式)

int16_t u_a = u_alpha;

int16_t u_b = (-1 * u_alpha + _INT16_SQRT3_ * u_beta / INT16_MAX) / 2;

int16_t u_c = -(u_a + u_b);

// 设置相电压

driver->setPhraseVoltage(u_a, u_b, u_c);

}

void BLDCMotor::open_loop_voltage_control(float target_ud, float target_uq)

{

uint16_t e_angle = this->electricalAngle();

float voltage_ud = _constrain(-limit_voltage, target_ud, limit_voltage);

float voltage_uq = _constrain(-limit_voltage, target_uq, limit_voltage);

int16_t u_d = this->sensor->directron * this->direction * (voltage_ud / power_supply_voltage * INT16_MAX);

int16_t u_q = this->sensor->directron * this->direction * (voltage_uq / power_supply_voltage * INT16_MAX);

this->setPhraseVoltage(u_d, u_q, e_angle);

}

/**

* 获取Q轴电流

*/

CurrentDQ BLDCMotor::getCurrentDQ()

{

CurrentDQ i = this->currentSensor->getCurrentDQ(this->electricalAngle());

return {

.d = this->current_d_filter(i.d),

.q = this->current_q_filter(i.q),

};

}

#include "foc_utils.h"

/**

* 电流闭环控制

*/

void BLDCMotor::close_loop_current_control(float target)

{

float target_i_d = 0;

float target_i_q = _constrain(-limit_current, target, limit_current);

CurrentDQ current = this->getCurrentDQ();

float error_d = target_i_d - current.d;

float error_q = target_i_q - current.q;

float u_d = this->pid_id_controller(error_d);

float u_q = this->pid_iq_controller(error_q);

this->open_loop_voltage_control(u_d, u_q);

static uint8_t idx = 0;

if (this->command && ++idx % 61 == 0)

{

idx = 0;

this->command->drawDragram(1, target_i_q, current.q);

}

}

/**

* 获取机械角速度

*/

float BLDCMotor::shaftVelocity()

{

return shaft_velocity_filter(this->sensor->getVelocity());

}

void BLDCMotor::close_loop_velocity_control(float target)

{

float target_velocity = _constrain(-limit_velocity, target, limit_velocity);

float current_velocity = this->shaftVelocity();

float error = target_velocity - current_velocity;

float i_q = this->direction * this->sensor->directron * this->pid_velocity_controller(error);

this->close_loop_current_control(i_q);

static uint8_t idx = 0;

if (this->command && ++idx % 62 == 0)

{

idx = 0;

this->command->drawDragram(2, target_velocity, current_velocity);

}

}

BLDCMotor.hpp#ifndef __BLDCMotor_H__

#define __BLDCMotor_H__

#include <stdint.h>

#include "foc_utils.h"

#include "BLDCDriver.hpp"

#include "LowPassFilter.hpp"

#include "CurrentSensor.hpp"

#include "Sensor.hpp"

#include "Timer.hpp"

#include "pid.hpp"

#include "Command.hpp"

class BLDCMotor : Timer

{

public:

enum ControlMode : uint8_t

{

Unknow = 0,

Voltage = 1,

Current = 2,

Velocity = 3,

Position = 4

};

enum MotorDirectrion : int8_t

{

UNKNOW = 0,

ANTI_CLOCK_WISE = 1,

CLOCK_WISE = -1,

};

// 极对数

uint8_t polePairs;

// 供电电压

float power_supply_voltage = 12.0f;

// 限制电压

float limit_voltage = 12.0f;

// 限制电流

float limit_current = 10.0f;

// 限制速度

float limit_velocity = 130.0f;

// directron

MotorDirectrion direction = MotorDirectrion::ANTI_CLOCK_WISE;

// taget

float target = 0;

// mode

ControlMode controlMode = ControlMode::Velocity;

// filter

LowPassFilter current_q_filter{5};

LowPassFilter current_d_filter{5};

LowPassFilter shaft_velocity_filter{50};

LowPassFilter shaft_angle_filter{100};

// pid-controller

PIDControler pid_iq_controller;

PIDControler pid_id_controller;

PIDControler pid_velocity_controller;

PIDControler pid_position_controller;

private:

//

BLDCDriver *driver = nullptr;

Sensor *sensor = nullptr;

CurrentSensor *currentSensor = nullptr;

Command *command = nullptr;

public:

BLDCMotor(uint8_t polePairs, float power_supply_voltage);

void connectDriver(BLDCDriver *driver);

void connectSensor(Sensor *sensor);

void connectCurrentSensor(CurrentSensor *currentSensor);

void connectCommand(Command *command);

void initFOC();

void loopFOC();

/**

* 设置控制模式

*/

void setMode(ControlMode mode);

void setTarget(float target);

/**

* 获取电角度

*/

uint16_t electricalAngle();

/**

* 设置相电压

* @param u_d int16_t [-32768,32767] 表示 [-1,1] 精度:1/32768 = 0.0000305

* @param u_q int16_t [-32768,32767] 表示 [-1,1]

* @param e_angle uint16_t [0,65535] 表示 [0,2PI] 精度:360°/65535 = 0.00549°

*/

void setPhraseVoltage(int16_t u_d, int16_t u_q, uint16_t e_angle);

/**

* 开环电压控制

*/

void open_loop_voltage_control(float target_ud, float target_uq);

/**

* 获取dq轴电流

*/

CurrentDQ getCurrentDQ();

/**

* 闭环电流控制

*/

void close_loop_current_control(float target);

/**

* 获取机械角速度

*/

float shaftVelocity();

/**

* 闭环速度控制

*/

void close_loop_velocity_control(float target);

};

#endif

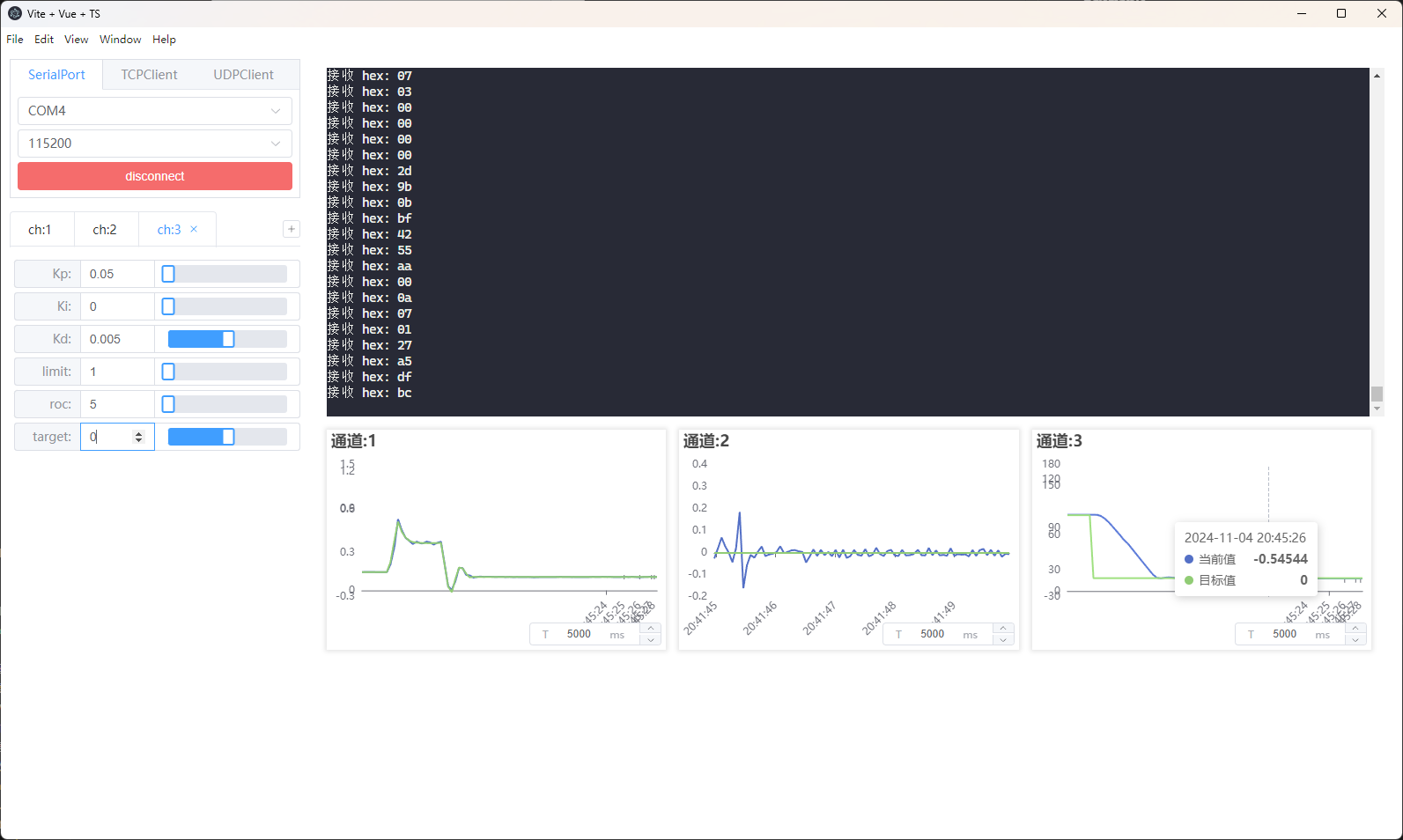

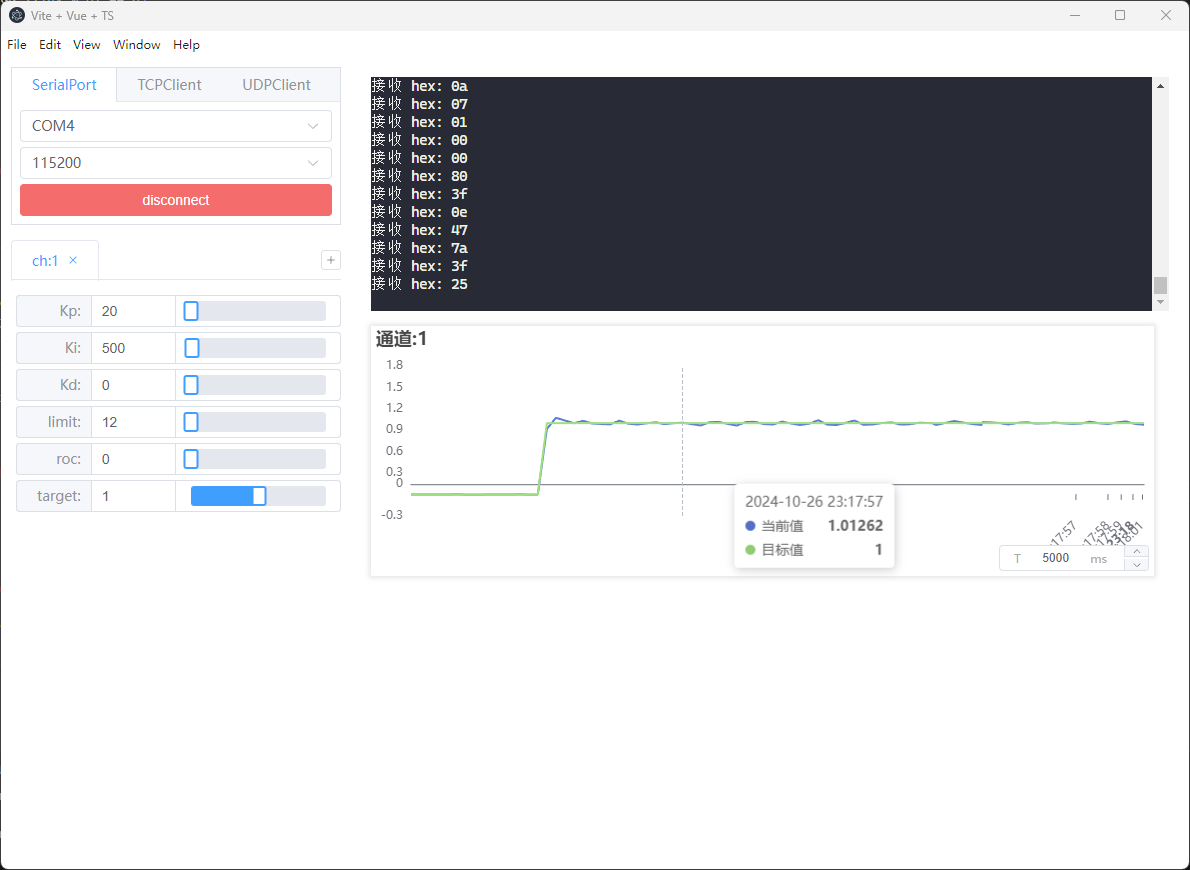

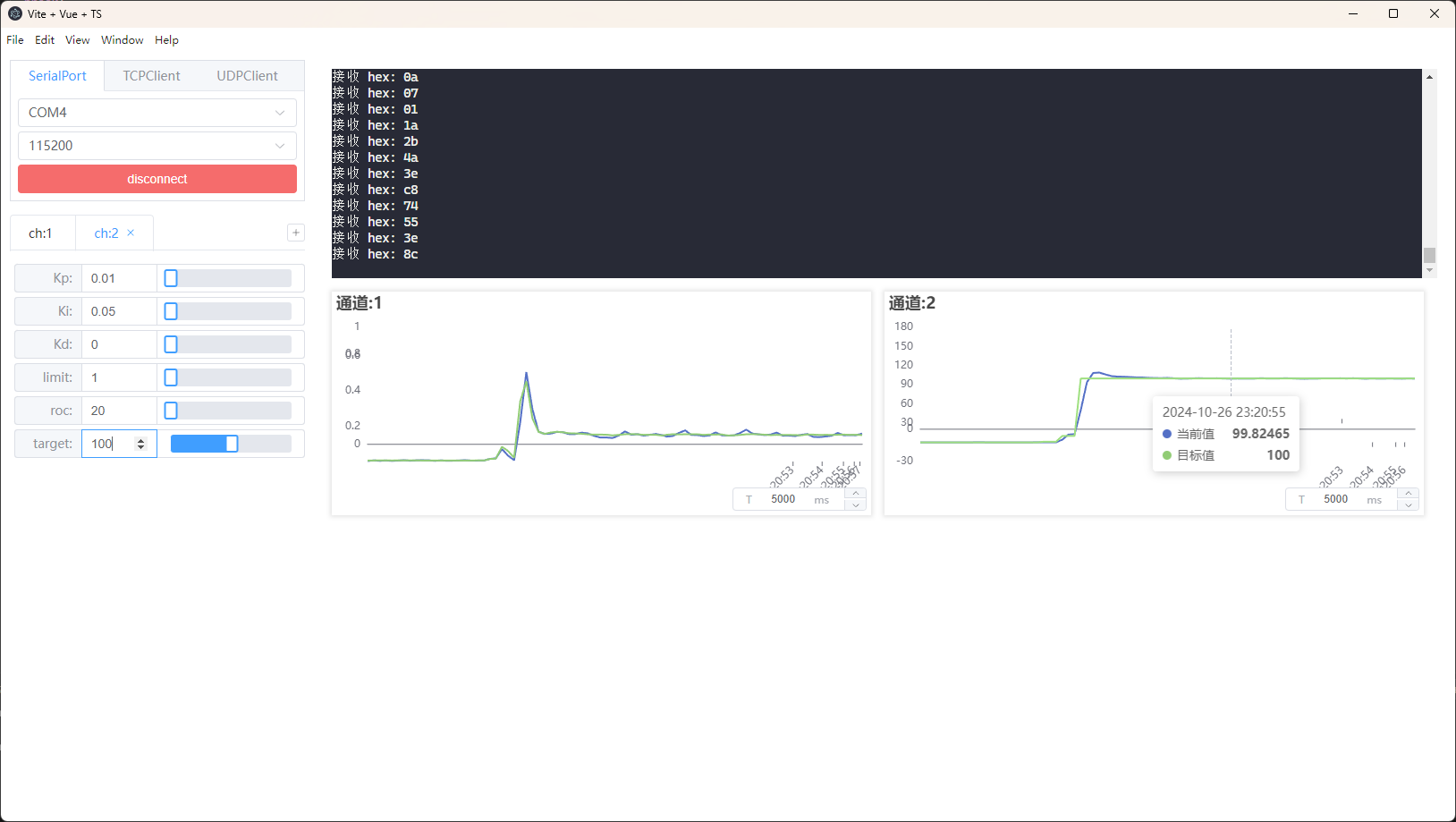

实现效果

电流闭环控制效果

速度闭环控制效果

代码

#include <Arduino.h>

#include <Wire.h>

#include "BLDCMotor.hpp"

#include "BLDCDriver.hpp"

#include "Sensor.hpp"

#include "foc_utils.h"

#include "typedef.h"

#include "pwm.h"

#include "Command.hpp"

BLDCMotor motor = BLDCMotor(7, 12);

#define M1_En 8

#define M1_Ua 5

#define M1_Ub 9

#define M1_Uc 6

PwmOut pwmA(D5);

PwmOut pwmB(D9);

PwmOut pwmC(D6);

BLDCDriver driver = BLDCDriver(

// init driver

[]()

{

pinMode(M1_En, OUTPUT); // enable

// pinMode(M1_Ua, OUTPUT); // a

// pinMode(M1_Ub, OUTPUT); // b

// pinMode(M1_Uc, OUTPUT); // c

// 20k

// period 50us = 20,000hz; pulse 0 us = 0%

// pwmA.begin(20000.0f, 0.0f);

// pwmB.begin(20000.0f, 0.0f);

// pwmC.begin(20000.0f, 0.0f);

// 10k

pwmA.begin(10000.0f, 0.0f);

pwmB.begin(10000.0f, 0.0f);

pwmC.begin(10000.0f, 0.0f);

},

// enable or disable driver

[](bool enable)

{

digitalWrite(M1_En, enable ? HIGH : LOW); // enable

},

// set pwm to driver

[](int16_t u_a, int16_t u_b, int16_t u_c)

{

// 设置占空比

// [-32768,32768] => [-1,1] => [-50,50] => [0,100]

pwmA.pulse_perc(u_a / 32768.0f * 50 + 50); // 设置百分比

pwmB.pulse_perc(u_b / 32768.0f * 50 + 50);

pwmC.pulse_perc(u_c / 32768.0f * 50 + 50);

});

#define AS5600_ADDR 0x36

#define AS5600_RAW_ANGLE 0x0c

#define AS5600_ANGLE 0x0e

Sensor sensor = Sensor(

[]()

{

// AS5600 最高支持1Mhz 1000000

Wire.setClock(1000000); // 100000 (standard mode) 400000 (fast mode) 1000000 (fast mode plus)

Wire.begin();

},

[]()

{

Wire.beginTransmission(AS5600_ADDR);

Wire.write(AS5600_ANGLE);

uint8_t err = Wire.endTransmission(false);

if (!!err)

{

// Wire.endTransmission(true);

// Serial.print("errorcode:");

// Serial.println(err);

return (uint16_t)0;

}

Wire.requestFrom(AS5600_ADDR, 2);

uint16_t data = 0;

*((uint8_t *)&data + 1) = Wire.read();

*((uint8_t *)&data + 0) = Wire.read();

err = Wire.endTransmission(true);

if (!!err)

{

// Serial.print("errorcode:");

// Serial.println(err);

return (uint16_t)0;

}

delay(1); // 这行代码解决了磁编码器有时无法读取的问题,开始怀疑时排针接触不良,然后尝试焊接排针问题依然存在,然后怀疑是SDA\SCL上拉电阻太多导致,拆掉问题依旧存在,然后怀疑是电机导致的电压波动,然后给AS5600供电加了个1uf和0.1uf电容,问题依旧,最后google搜索后发现别人的代码中有delay遂加上,问题解决.

// as5600 12bit精度,左移4位变成16位

data <<= 4;

// Serial.println(data);

return data;

});

#include "CurrentSensor.hpp"

#define M1_Ia A0

#define M1_Ib A2

#define M1_Ic

#define I_R 0.01f // 10mΩ

CurrentSensor currentSensor = CurrentSensor(

[]()

{

pinMode(M1_Ia, INPUT);

pinMode(M1_Ib, INPUT);

// Arduino 板上的标准分辨率为 10 位 (0-1023)

analogReadResolution(14); // UNO R4 支持高达 14 位(0-16383)的分辨率

analogReference(AR_DEFAULT); // 默认参考电压 5 V

// analogReference(AR_INTERNAL); // 内置参考电压 1.5 V

},

[]()

{

// [0,16383] => [0,5]

return CurrentABC{

// i = u/r

.a = (analogRead(M1_Ia) / 16383.0f * 5.0f - 2.5f) / 0.01f / 50,

.b = -(analogRead(M1_Ib) / 16383.0f * 5.0f - 2.5f) / 0.01f / 50, // b电路接反了 加符号

};

});

Command command;

void setup()

{

Serial.begin(115200);

motor.connectDriver(&driver);

motor.connectSensor(&sensor);

motor.connectCurrentSensor(¤tSensor);

command.connectMotor(&motor);

command.connectSerial(&Serial);

motor.connectCommand(&command);

motor.initFOC();

motor.setMode(BLDCMotor::ControlMode::Current);

}

void loop()

{

motor.loopFOC();

command.update();

// Serial.println(sensor.getPositon());

}